Meet the Meatmakers

From Mushroom Roots to Lab-Grown Fat: Inside Berlin's Pioneering Food Tech Scene

Berlin's unique ecosystem has become a magnet for brilliant minds from across the globe. The city offers the perfect environment for developing cutting-edge technologies – affordable lab space, a collaborative startup culture, and a population eager to embrace sustainable innovations. It's no wonder that food tech visionaries are flocking here, turning the German capital into a hub for reimagining what's on our plates.

Let's meet six remarkable Berlin-based companies that are changing the game when it comes to the next generation of meat. Each brings something special to the table – literally.

Esencia Foods: Ocean Flavors Without the Catch

What makes them special: They're using mushroom mycelium to create seafood alternatives with authentic texture and umami flavor.

When you first hear "fish alternatives made from mushroom roots," it might not sound particularly appetizing. But Esencia Foods is making fungi sexy.

Founded by passionate innovators Hendrik and Bruno – a professional cook and a quality-focused entrepreneur – Esencia has developed a technology platform that can replicate different types of fish and seafood using mycelium solid-state fermentation. They draw inspiration directly from nature's playbook.

What sets them apart from other plant-based fish alternatives? For starters, there are about 6-10 times more fungi species than plants on Earth. While we happily eat processed peas and soybeans in other fish alternatives, mycelium remains underutilized in our diets despite being protein-rich and naturally providing that coveted umami flavor.

Most importantly, mycelium grows in complex structures that allow Esencia to mimic fish muscle fibers – creating unique flavor explosions without ingredient labels longer than those on face cream. Their technology is so promising that in February 2025, they secured a €2 million grant and equity investment from the European Innovation Council (EIC) Accelerator.

The company has been rapidly expanding its mycelium solid-state fermentation platform (patent filed) to serve various products beyond seafood, including vegan minced meat, chicken pieces, kebab strips, and even steak. They've scaled production from grams to hundreds of kilograms per batch by cleverly retrofitting existing infrastructure from adjacent sectors.

With a growing team of nine full-time equivalents and partnerships ranging from leading German supermarkets to premium caterers, Esencia Foods is proving that sustainable seafood alternatives can be both delicious and scalable.

Nosh.bio: One Ingredient, Endless Possibilities

What makes them special: Their single-ingredient fungal protein can replace meat, eggs, stabilizers, and more across countless food applications.

While many alternative protein companies focus solely on creating meat substitutes, Nosh.bio is thinking bigger. This ambitious Berlin startup creates nutritional and highly functional proteins from non-GMO fungi using a proprietary fermentation process that's minimal, scalable, and sustainable.

Their approach yields a versatile ingredient with the cleanest of labels – a superior source of protein, nutrition, and functionality that can be tailored to diverse needs. And they're not just talking about meat alternatives. Nosh.bio's fungal protein can serve as a replacement for seafood, eggs in baked goods, stabilizers in dairy products (both plant-based and conventional), protein enrichment in chocolate, thickening agents in sauces, and protein-packed snacks and drinks.

The star of their show is "Koji Chunks," bite-sized pieces with a texture remarkably similar to tender pork. The chunks offer the satisfying juiciness and chew of meat, with a mild natural flavor that serves as the perfect canvas for various seasonings and sauces.

What's truly revolutionary about Nosh.bio's approach is the simplicity. Their pure product contains just one ingredient – the Japanese filamentous fungus Koji, which has been used for thousands of years in traditional Japanese cuisine to make soy sauce and miso paste.

The production process is elegantly straightforward: Koji mycelium grows in a sugar-containing liquid, which it metabolizes through fermentation. After just 48 hours, the protein-rich fibers are harvested, pressed, and transformed into food products. Production takes place in a former brewery in Saxony, with plans to eventually feed the fungi on byproducts from food manufacturing, such as starchy water from industrial potato processing.

Project Eaden: Spinning Plant Fibers Into Meaty Magic

What makes them special: They've adapted textile industry technology to create ultra-realistic plant-based meats through fiber spinning.

Sometimes the most innovative solutions come from unexpected places. Project Eaden's breakthrough idea was born when co-founders Jan Wilmking, a former Zalando manager, and David Schmelzeisen, who holds a PhD in textile engineering, realized they could apply spinning technology from the textile industry to recreate meat in scalable and affordable ways.

The company has developed a cutting-edge platform technology that uses proprietary fiber spinning to create plant-based meats with the look, taste, and chew of animal meat. Their products are so convincing they've earned endorsements from butchers, Michelin chefs, and retail buyers.

The timing couldn't be better. With livestock farming responsible for 12% of total annual greenhouse gas emissions and global demand for meat growing, Project Eaden's mission is to make the switch away from animal meat consumption "a no-brainer" by delivering on taste, texture, and nutrition.

Their vision is gaining serious traction. In January 2025, the company raised an oversubscribed €15 million Series A funding round led by Planet A and REWE Group, bringing their total funding to €27 million. The investment will support their European retail launch, beginning with Germany in mid-2025, where their ultra-realistic ham products will debut in thousands of REWE supermarkets across the country.

The environmental benefits are substantial. Each kilogram of Project Eaden's product reduces greenhouse gas emissions by up to 20 kg CO₂-eq (equivalent to driving about 100 kilometers in a fossil-fuel car), and water use by up to 56 m³ (comparable to the daily consumption of 660 Europeans).

Based in Berlin's buzzing Kreuzberg neighborhood, their small but mighty team of 30 material and food scientists, mechanical engineers, and business professionals are creating the future of meat – one fiber at a time.

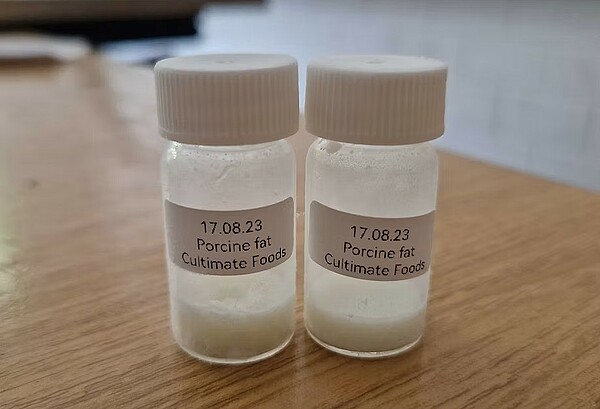

Cultimate Foods: The Best of Both Worlds

What makes them special: They're creating hybrid products combining plant-based protein with cell-cultivated fat for authentic taste.

Many consumers trying plant-based meat alternatives find themselves disappointed with the taste and texture, unwilling to compromise on their culinary experience. Cultimate Foods has identified a unique opportunity to bridge this gap with hybrid products – combining plant-based protein with cell-based ingredients, specifically cultivated fat.

The company is developing a game-changing alternative fat ingredient that brings authentic meaty taste and texture to plant-based meat products. Using modern cellular agriculture technologies, they grow real fat cells without any harm to animals.

Their approach acknowledges a fundamental challenge: global meat consumption is growing steadily and expected to double by 2050. While factory farming drives climate change and harms the environment, many existing meat alternatives simply don't satisfy consumers who prioritize taste.

Cultimate Foods' revolutionary ingredient aims to elevate plant-based meats to a level that truly rivals traditional meat, potentially accelerating the adoption of meat alternatives by appealing to taste-conscious consumers who have previously rejected plant-based options.

By focusing specifically on fat – the component that delivers much of meat's distinctive flavor and mouthfeel – Cultimate Foods has found a strategic niche that could transform the entire alternative protein landscape.

Pacifico Biolabs: Whole-Muscle Meat Without Animals

What makes them special: They're creating whole-muscle meats through mycelium fermentation that integrate directly into existing meat supply chains.

Pacifico describes itself as "a meat company, reinvented." Their goal is not to provide a vegan substitute for meat, but to create the next generation of meat - no animals involved. “After two decades of trying to replace meat with overly-formulated plant-based products, it’s time to change tactics and give consumers what they want: something as delicious, nutritious, and simple as meat,” they say on their website.

Unlike many alternative protein startups that create new product categories, Pacifico provides delicious meat to B2B customers that they can cut, cook, and create with – just like legacy meat companies.

Pacifico's innovation lies in the science behind their mycelium fermentation. By combining the natural power of fermentation with advanced biotechnology, they've created a highly efficient protein production platform. Their process feeds sugars to fungi, which convert them into whole-muscle, meaty Viando protein.

The company is positioning itself not as a maker of "meat alternatives" but as a new kind of meat producer – one that delivers the same culinary experience and supply chain convenience without the environmental and ethical concerns of animal agriculture.

BettaF!sh: Seaweed Innovation Redefining Seafood Alternatives

What makes them special: They're leveraging European seaweed and legume proteins to create authentic seafood alternatives that promote sustainable ocean conservation.

While Esencia Foods uses fungal mycelium as the basis for seafood alternatives, BettaF!sh takes a different but equally innovative approach. The Berlin-based startup harnesses the natural properties of seaweed to reinvent popular seafood products without harming marine ecosystems.

Their approach is refreshingly simple - seaweed serves as nature's flavor powerhouse to recreate the authentic taste of fish. By combining these algae with proteins from field beans and peas, they've created products that not only taste like the original, but also provide significant nutritional benefits.

BettaF!sh's flagship products, TU-NAH and SAL-NOM, take on two of the world's most popular fish. Their TU-NAH offers a compelling alternative to canned tuna that's completely plant-based, soy-free and wheat-free, while providing both protein and fiber. Meanwhile, their SAL-NOM offers a remarkably authentic plant-based smoked salmon alternative that even serves as a source of omega-3 fatty acids-typically the nutritional benefit cited for eating fish in the first place.

The company's vision extends beyond the creation of finished products. They're actively advancing the research and development of seaweed as a sustainable food ingredient, working with prestigious partners such as the Fraunhofer Institute IMTE to unlock the full potential of this underutilized resource. Their goal is to develop clean-label seaweed ingredients that can be widely adopted throughout the food industry.

Berlin: The Perfect Environment for Food Innovation

Berlin's emergence as a center for food technology innovation isn't accidental. The city offers a unique combination of factors that make it ideal for pioneering startups in this space.

The German capital is continuously developing into the center of Germany's food tech scene, particularly in plant-based, cell-based, and precision-fermented foods. The food market is evolving rapidly, creating new value creation potential and technical solutions in areas such as personalized nutrition and sustainable, healthy products.

Want to learn more about food tech in Berlin?

Feel free to contact Jens Woelki from Berlin Partner anytime. Berlin Partner is the city's economic development agency and will support you free of charge if you're interested in engaging in business in Berlin.

---

Header image: © Project Eaden